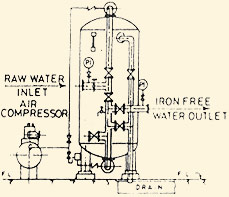

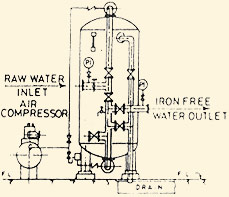

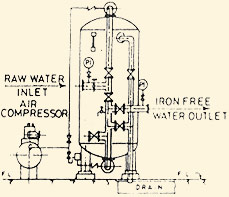

IRON REMOVAL FILTER

OPERATION

Iron removal filter is manually operated processed catalytic

filtration unit when the raw water passed through the layer of

compressed air, processed catalyst & quartz filter media

respectively. The dissolved ferrous iron salts are converted into

insoluble ferric salt and precipited over the filter bed and then

the iron free filtered water comes out. Only backwashing with

clear water and compressed air" is required for cleaning the bed.

CONSTRUCTION

Mild Steel Welded Pressure Vessel fitted with M. S. Control pipe &

C.I. diaphragm valve, strainers, sampling cock, pressure gauge, air

compressor and first charge filter media.

APPLICATION

(i) Hotels (ii) Hospital (iii) P.H.E. (iv) Housing Flats (v) Tea

Garden

(vi) Industry etc.

ADVANTAGE

|

Remove Yellow stains from clothes. |

|

Prevents bacteria and

stomach/gastric disorder. |

|

Prevents corrosion & clogging of

pipe line. |

|

Keeps Bathrooms / kitchens clear. |

FLOW RANGE

50 litres/hr to 50.000

litres/hr.

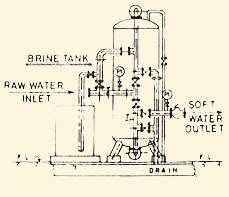

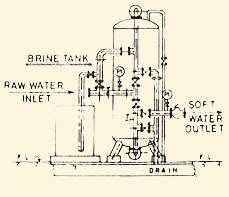

BASE EXCHANGE SOFTENER

OPERATION OPERATION

Water softener is manually operated

ion exchange unit charged with cation exchange resin operation in

sodium cycle. When the raw water free from Iron & suspended solids

passed through the resin bed downwardly the scale forming hardness

salts are exchanged with the non-scale forming sodium salts and

produces hardness free soft water. Only ordinary Commercial grade

common salt is required for re-charging the exhausted resin.

CONSTRUCTION

Mild Steel Welded Pressure Vessel fitted with M. S. Control pipe &

C.I. diaphragm valve, strainers, sampling cock, pressure gauge, and

first charge ion exchange resin.

APPLICATION

Boiler, Heat Exchanger, Chemical Industry, Textile Processing, Air

Conditioning. Hotels Housing flats etc.

ADVANTAGE

|

Reduces soap & detergent

consumption. |

|

Cooking time fastener & reduces

fuel consumption. |

|

Prevents Hair loss. |

|

Longer life for geysers, washing

machine. |

|

Prevent scale forming in boiler,

heat exchanger & Pipeline. |

FLOW RANGE

50 litres/hr to 50.000

litres/hr.

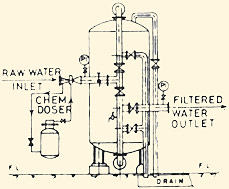

ACTIVATED CARBON FILTER

OPERATION

Activated Carbon filter is manually operated filtration unit.

When the raw water passes downwardly through the laver of

activated carbon the chlorine, colour, odour and organics are

obsorbed by the activated carbon media and produces colour,

odour and organics free pure clear filtered water. Only

backwashing with clear water is required for cleaning the bed.

CONSTRUCTION

Mild Steel Welded Pressure Vessel fitted with M. S. Control

pipe & C.I. diaphragm valve, strainers, sampling cock,

pressure gauge, and first charge carbon media.

APPLICATION

Potable Water, Oil Removal, Effluent Plant, Chemical Plant,

Boiler Feed.

ADVANTAGE

|

Removes Colour & Odour from

portable water. |

|

Removes organic matter. |

|

Removes oil traces & chlorine. |

FLOW RANGE

50 litres/hr to 50.000

litres/hr.

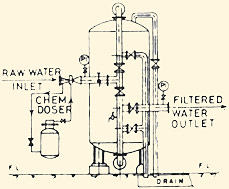

PRESSURE FILTER

OPERATION

Pressure filter is manually

operated filtration unit. When the raw water passes downwardly

through the layer of graded gravel and quartz sand, the

colloids and suspended matters are trapped and accumulated on

the bed and produces clear filtered water. Only backwashing

with clear water is required for cleaning the bed.

CONSTRUCTION

Mild Steel Welded Pressure Vessel fitted with M. S. Control

pipe & C.I. diaphragm valve, strainers, sampling cock,

pressure gauge, air blower (optional), and first charges of

filtering media.

APPLICATION

Potable Water, Cooling water circuits, Swimming pool, Chemical

Plant, Public Heath, effluent plant filtration.

ADVANTAGE

|

Remove turbidity & colloidals. |

|

Removes suspended particles. |

|

Delivers high clarity sparking

filtered water. |

FLOW RANGE

50 litres/hr to 50.000

litres/hr.

|

OPERATION

OPERATION